Adjusting Zero Point on Continuous Rotation Servo

FEETECH FS90R micro continuous rotation servo with a LEGO Minifigure as a size reference

Bottom view of FEETECH FS90R micro continuous rotation servo (V1.0) showing middle-point adjustment potentiometer. FS90R V2.0 uses an SMD potentiometer

Overview

The FS90R is a micro-sized servo that has been built by FEETECH (formerly known as Fitec) specifically for continuous rotation. At 6 V, it has a maximum rotation speed of around 130 RPM (no-load) and can produce up to 21 oz-in (1.5 kg-cm) of torque. The servo can be controlled using a direct connection to a single microcontroller I/O line without any additional electronics, which makes it a great miniature actuator for beginner robotics projects; just throw on a pair of wheels and your robot is ready to roll!

The FS90R continuous rotation servo converts standard RC servo position pulses into continuous rotation speed. The default rest point is 1.5 ms, but this can be adjusted by using a small screwdriver to turn the middle-point adjustment potentiometer. Pulse widths above the rest point result in anti-clockwise rotation, with speed increasing as the pulse width increases; pulse widths below the rest point result in clockwise rotation, with speed increasing as the pulse width decreases.

The servo has a 7″ (180 mm) lead that is terminated with a JR-style connector and includes additional servo horns and mounting hardware. The following picture shows an example of the hardware that might be included (actual hardware could vary):

This robotics servo, which is a continuous rotation version of the FEETECH (Fitec) FS90, is compatible with our servo controllers. If you are looking for a similar servo that is capable of limited-range position control as opposed to continuous rotation speed control, consider the Power HD micro servo HD-1900A, which has almost the same weight, speed, and torque as the FS90R.

Note: As of December 3, 2014, we are shipping V2.0 of this servo, which widens the deadband from ±5 μs to ±45 μs to make it easier to set a stationary neutral position. Also, the middle-point adjustment potentiometer has been changed to a lighter SMD potentiometer on the new version. The physical dimensions of the servo have not changed.

Wheels

If you want to use this servo as an actuator for your miniature robot, you will need a wheel to go with it. Fortunately, we carry a 60×8 mm wheel specifically designed for use with this servo:

| Pololu Wheel for FEETECH FS90R Micro Servo, 60x8mm, mounted on an FS90R micro servo | Pololu Wheel for FEETECH FS90R Micro Servo, 60x8mm, mounted on an FS90R micro servo (1) | Pololu Wheel for FEETECH FS90R Micro Servo, 60x8mm, mounted on an FS90R micro servo (2) (2) |

The wheel size is well matched to the servo's speed and torque, allowing for a top speed of around 40 cm/s (1.3 ft/s) at 6 V.

Continuous rotation servo comparison

Continuous rotation servo size comparison. From left to right: SpringRC SM-S4303R, Power HD AR-3606HB, Parallax, and FEETECH FS90R

- What are the three wires coming out of my servo?

-

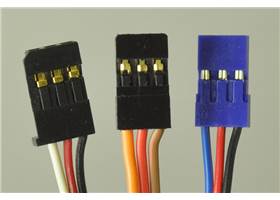

Pololu - Common RC servo connectors. From left to right: Futaba, JR, Airtronics Z

Most standard radio control servos (and all RC servos we sell) have three wires, each a different colour. Usually, they are either black, red, and white, or they are brown, red, and orange/yellow:

- brown or black = ground (GND, battery negative terminal)

- red = servo power (Vservo, battery positive terminal)

- orange, yellow, white, or blue = servo control signal line

Please check the specs for your servo to determine the proper power supply voltage, and please take care to plug the servo into your device in the proper orientation (plugging it in backwards could break the servo or your device).

Source: https://www.robotgear.com.au/Product.aspx/Details/4544-FEETECH-FS90R-Micro-Continuous-Rotation-Servo

0 Response to "Adjusting Zero Point on Continuous Rotation Servo"

Post a Comment